Venev Unicorn³ Series Dual-Sided Resin-Bonded CBN Stones are designed for use in sharpening systems such as Hapstone and TSProf, as well as for freehand sharpening. CBN (Cubic Boron Nitride) is the second-hardest material after diamond, offering exceptional wear resistance and thermal stability. CBN sharpening stones provide excellent performance when working with high-alloy, powder, and hardened steels.

The Unicorn³ Series represents Venev’s premium-tier dual-sided stones, featuring 3mm CBN-bearing layers bonded to a CNC-milled aircraft-grade aluminum alloy plate. The CBN-bearing layers contain evenly distributed CBN grains within a resin bond. The abrasive layer thickness in the Unicorn³ Series is twice that of the Centaur Series.

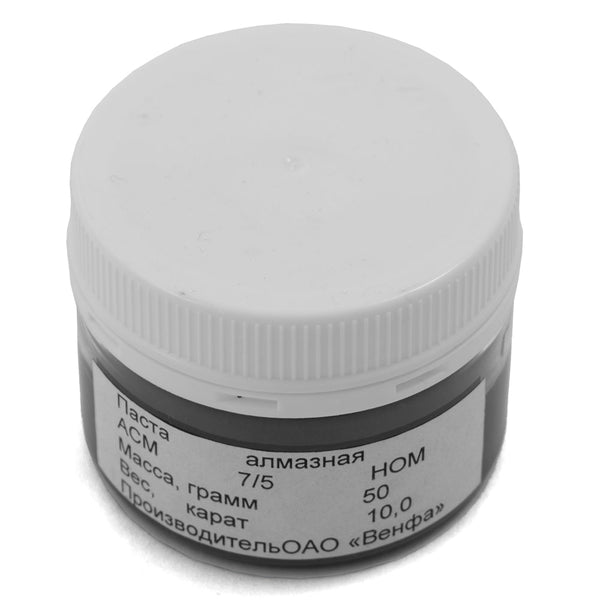

Grits F80–F240 utilize a wear-resistant boron-modified phenolic resin composite binder (legacy binder). Grits F400–F1200 use a proprietary non-abrasive phenolic resin composite binder (OSB binder), providing scratch-free sharpening results.

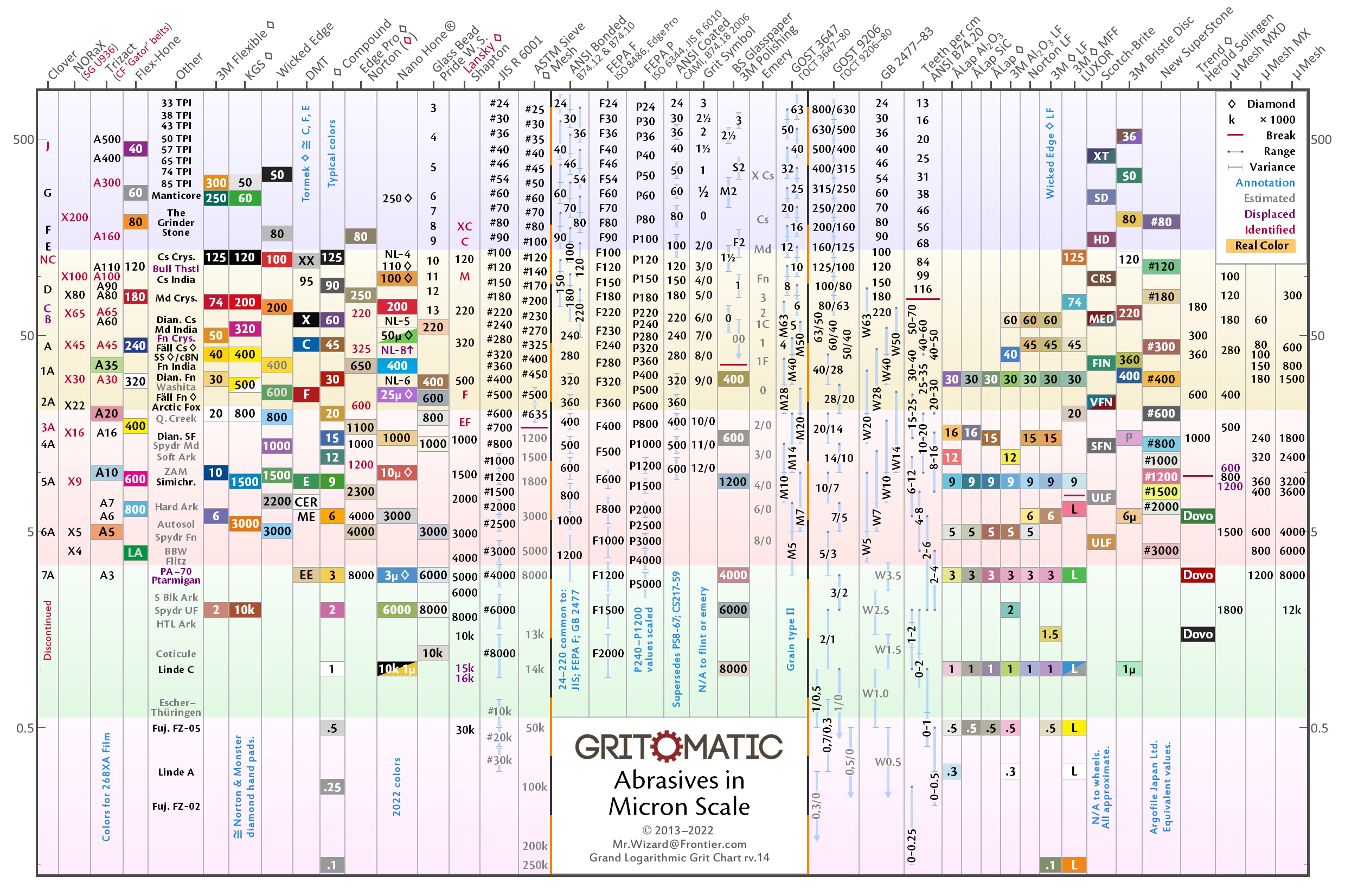

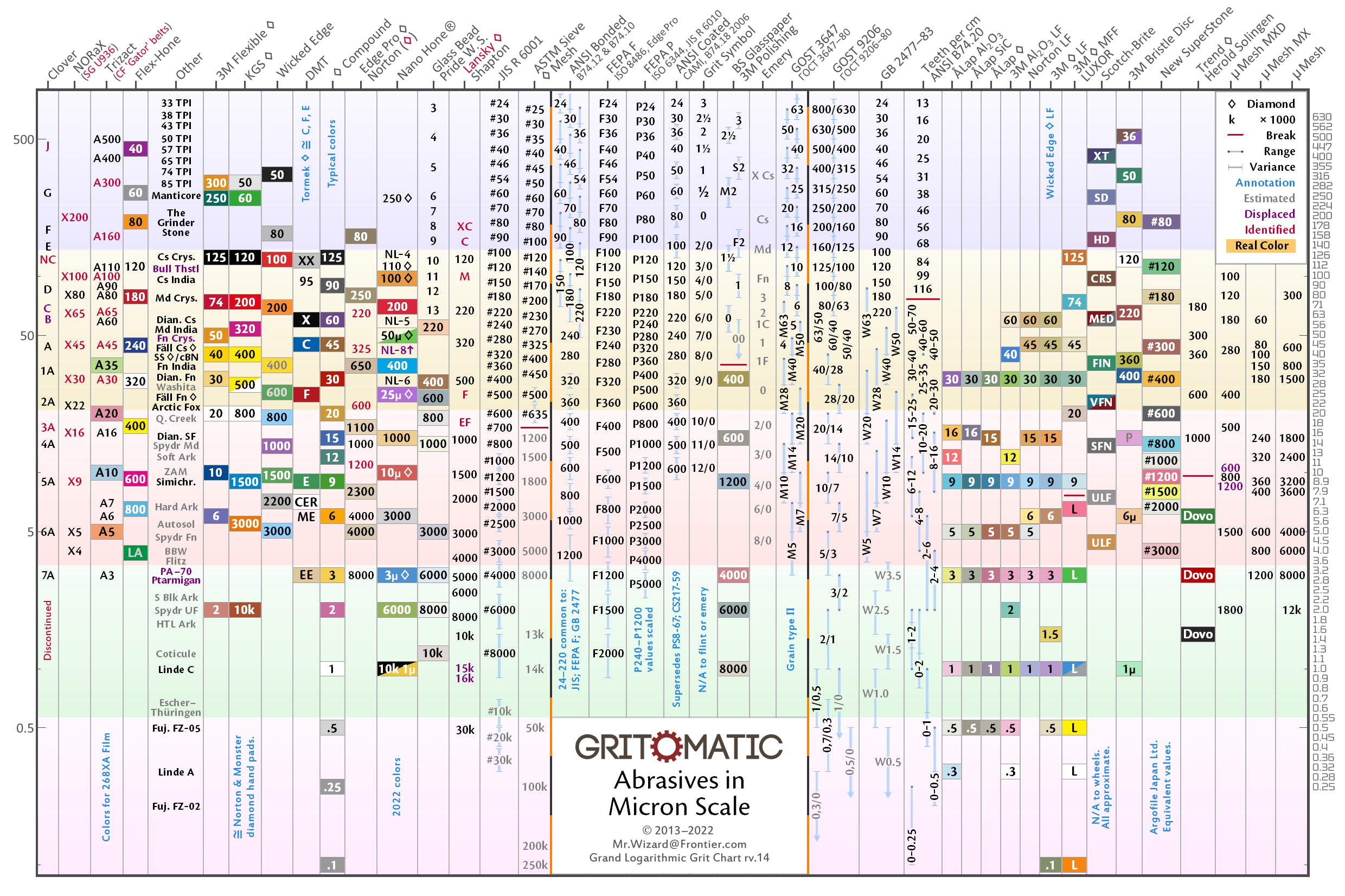

All Venev CBN stones use FEPA-F grit classification.

⚠️ Attention: Due to the increased thickness of 14mm, Unicorn and Unicorn³ Series stones are not compatible with any stone cases currently offered. The only suitable storage option for the Unicorn Series is the Roll Bag for 6 stones.

| Code | Diamond Series | CBN Series | Dimensions | Bond | Class |

|---|---|---|---|---|---|

| CBR | Cerberus | 100×17×10×2×2 | Resin | Dual‑sided Premium | |

| UMI | Ursa | 150×16×10×1×1 | Resin | Dual‑sided Standard | |

| CEN | Centaur | Centaur³ | 150×25×10×1×1 | Resin | Dual‑sided Standard |

| MON | Unicorn🚀 | Unicorn³🚀 | 150×25×14×3×3 | Resin | Dual‑sided Premium |

| CMA | Greater Dog | 98×40×10×1×1 | Resin | Dual‑sided Standard | |

| PHE | Phoenix | 200×83×10×1×1 | Resin | Dual‑sided Standard | |

| DRA | Dragon | 200×83×12×2×2 | Resin | Dual‑sided Premium | |

| CHA | Chameleon🚀 | Chameleon³🚀 | 150×25×6×3×3 | Metallic | Dual‑sided Solid |

| SCO | Scorpion | 100×25×8×2 | Resin | Single‑sided Mounted | |

| ORI | Orion | Orion³ | 150×25×6×3 | Resin | Single‑sided Mounted |

| SGR | Archer 𝘎𝘦𝘯𝟤⌛ | Archer³ | 150×25×3 | Metallic | Single‑sided Variative |

| GEM | Gemini 𝘎𝘦𝘯𝟤🚀 | 150×12×3 R40 | Metallic | Single‑sided Mounted | |

| SCL | Sculptor🚀 | 150×12×3 | Metallic | Single‑sided Mounted |

Resin Dual Premium Resin Dual Standard Resin Single Mounted 🚀 Released ⌛ Soon

Dimensions notation.

Monolayer solid abrasives have 3 numbers: length × width × thickness.

Single-sided abrasives with backing have 4 numbers: length × width × full thickness × thickness of abrasive.

Dual-sided abrasives have 5 numbers: length × width × full thickness × thickness of abrasive #1 × thickness of abrasive #2 (both sides)

If thickness is variable, the minimum thickness is noted.

For curved abrasives, a radius of curvature inmm is added: R40.

Metallic Binders (MMC)

- M2-01 - Copper-tin bronze alloy.

- MS-1 - Metal-matrix composite (MMC) - Copper-tin bronze alloy reinforced with silicon carbide.

- MB-1 - Metal-matrix composite (MMC) - Copper-tin bronze alloy reinforced with boron carbide.

- MS-1A - Metal-matrix composite (MMC) - Aluminum-copper alloy reinforced with silicon carbide.

Resin Binders

- B1-10 - Boron-modified phenolic resin (BPF) composite - Made of powdered bakelite, copper additive

- B2-01 - Boron-modified phenolic resin (BPF) composite - Made of liquid bakelite, iron additive (softer than В1-10)

- В2-01М - Boron-modified phenolic resin (BPF) composite - Made of liquid bakelite, copper additive (softer than В2-01)

- OSB (OCB) – A proprietary phenolic resin composite.

(OSB and OCB refer to the same binder; the difference arises from a transliteration quirk of the Cyrillic “ОСБ,” which can be rendered as either “OSB” or “OCB” in Latin script.)

![Venev Unicorn³ Series Dual Side Resin CBN [6" x 1"]](http://de.gritomatic.com/cdn/shop/files/Venev_20Unicorn_20Shade-5_490x.progressive.jpg?v=1764726662)

![Venev Unicorn³ Series Dual Side Resin CBN [6" x 1"]](http://de.gritomatic.com/cdn/shop/files/Venev_20Unicorn_20CBN_20_282_29_490x.progressive.jpg?v=1764726662)

![Venev Unicorn³ Series Dual Side Resin CBN [6" x 1"]](http://de.gritomatic.com/cdn/shop/files/Venev_20Unicorn_20CBN_20All_20_281_29_490x.progressive.jpg?v=1764726662)

![Venev Unicorn³ Series Dual Side Resin CBN [6" x 1"]](http://de.gritomatic.com/cdn/shop/files/Venev_20Unicorn_20CBN_20All_20_282_29_490x.progressive.jpg?v=1764726662)

![Venev Unicorn³ Series Dual Side Resin CBN [6" x 1"]](http://de.gritomatic.com/cdn/shop/files/Venev_20Unicorn_20CBN_20Set_20_281_29_490x.progressive.jpg?v=1764726662)

![Venev Unicorn³ Series Dual Side Resin CBN [6" x 1"]](http://de.gritomatic.com/cdn/shop/files/Venev_20Unicorn_20Shade-5_70x.progressive.jpg?v=1764726662)

![Venev Unicorn³ Series Dual Side Resin CBN [6" x 1"]](http://de.gritomatic.com/cdn/shop/files/Venev_20Unicorn_20CBN_20_282_29_70x.progressive.jpg?v=1764726662)

![Venev Unicorn³ Series Dual Side Resin CBN [6" x 1"]](http://de.gritomatic.com/cdn/shop/files/Venev_20Unicorn_20CBN_20All_20_281_29_70x.progressive.jpg?v=1764726662)

![Venev Unicorn³ Series Dual Side Resin CBN [6" x 1"]](http://de.gritomatic.com/cdn/shop/files/Venev_20Unicorn_20CBN_20All_20_282_29_70x.progressive.jpg?v=1764726662)

![Venev Unicorn³ Series Dual Side Resin CBN [6" x 1"]](http://de.gritomatic.com/cdn/shop/files/Venev_20Unicorn_20CBN_20Set_20_281_29_70x.progressive.jpg?v=1764726662)

![Venev Orion Series Diamond [6 "x 1"]](http://de.gritomatic.com/cdn/shop/files/venev-bonded-diamond-for-edge-pro_600x.progressive.jpg?v=1764726752)

![Venev Centaur -Serie Dual Side Diamond [6 "x 1"]](http://de.gritomatic.com/cdn/shop/files/6-x-1-dual-side-bonded-diamond_600x.progressive.jpg?v=1764726757)

![Venev Centaur -Serie Dual Side Diamond (3) Steinset [6 "x 1"]](http://de.gritomatic.com/cdn/shop/files/6-x-1-dual-side-bonded-diamond-full-set_600x.progressive.jpg?v=1764726778)